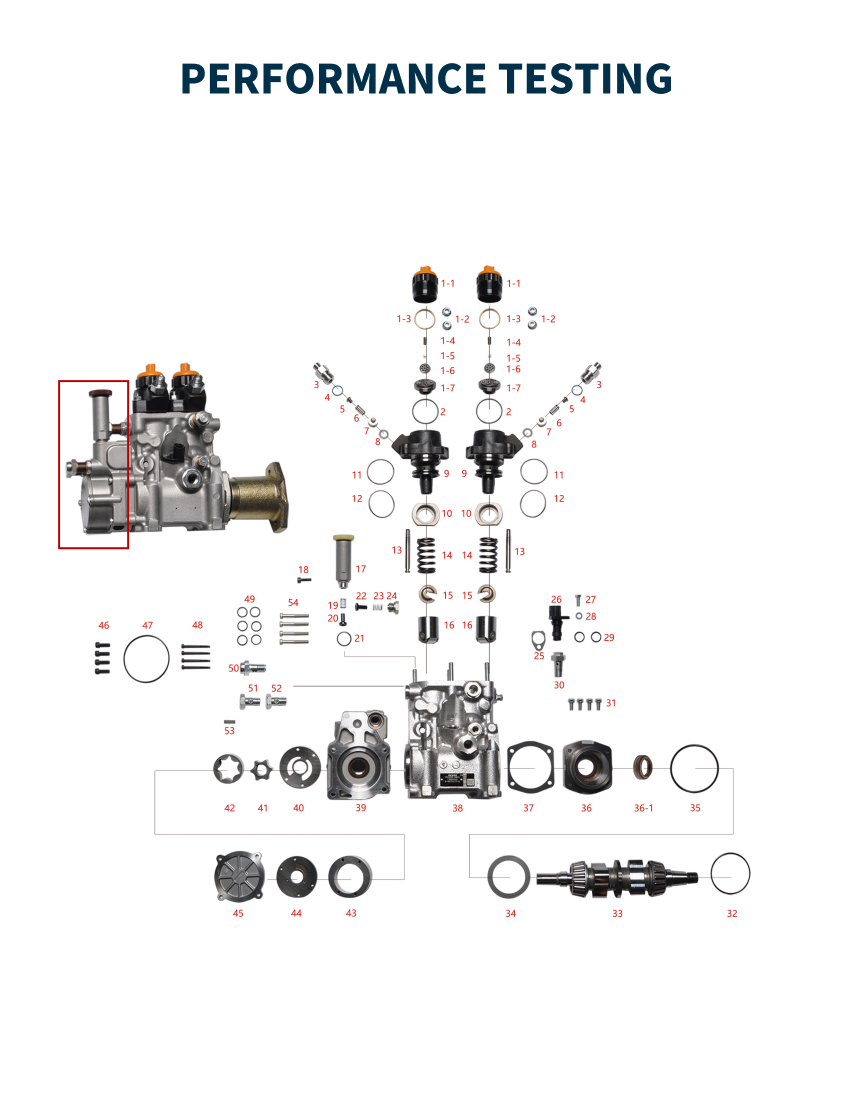

Performance Test

Discover the detailed performance test of common rail diesel pumps at commonraildieselpumps.com. Our assessment includes various factors like electrical characteristics, precision, resilience in extreme temperatures, pressure resistance, and leak prevention. Browse through our catalog to ensure that your selection of common rail diesel pumps meets the highest performance standards tailored to your specific requirements.

After the production of common rail diesel pumps is completed, the tests mentioned above need to be conducted. However, regular checks are also crucial to maintain optimal performance.

To ensure the proper functioning of Common rail diesel pumps, certain components need regular inspection before installation:

1. Inspect the guide sleeve, spring, gasket, and tight cap of the Common rail diesel pumps for deformation, cracking, thread damage, quenching, leakage, and rust. The tight cap should be replaced after disassembly for more than 5 times.

2. Replace the tight cap and copper gasket of the Common rail diesel pumps.

3. Check if the gap between the common rail diesel pumps needle and the shell falls within the standard range for proper operation.

4. Examine all parts for wear under a microscope at least 20 times magnification.

5. Deformation, cracking, thread damage, quenching, leakage in the tight cap of the Common rail diesel pumps can result in vehicle emission issues and fuel pump damage.

6. Deviation of the diesel pump opening pressure from the specified range may cause fuel pump damage.

7. Neglecting to replace worn-out parts promptly during maintenance can lead to fuel pump damage.

These precautions are essential for the maintenance of Common rail diesel pumps. For additional queries about Common rail diesel pumps or other issues, feel free to reach out to us at commonraildieselpumps.com, and we will assist you to resolve your concerns effectively.