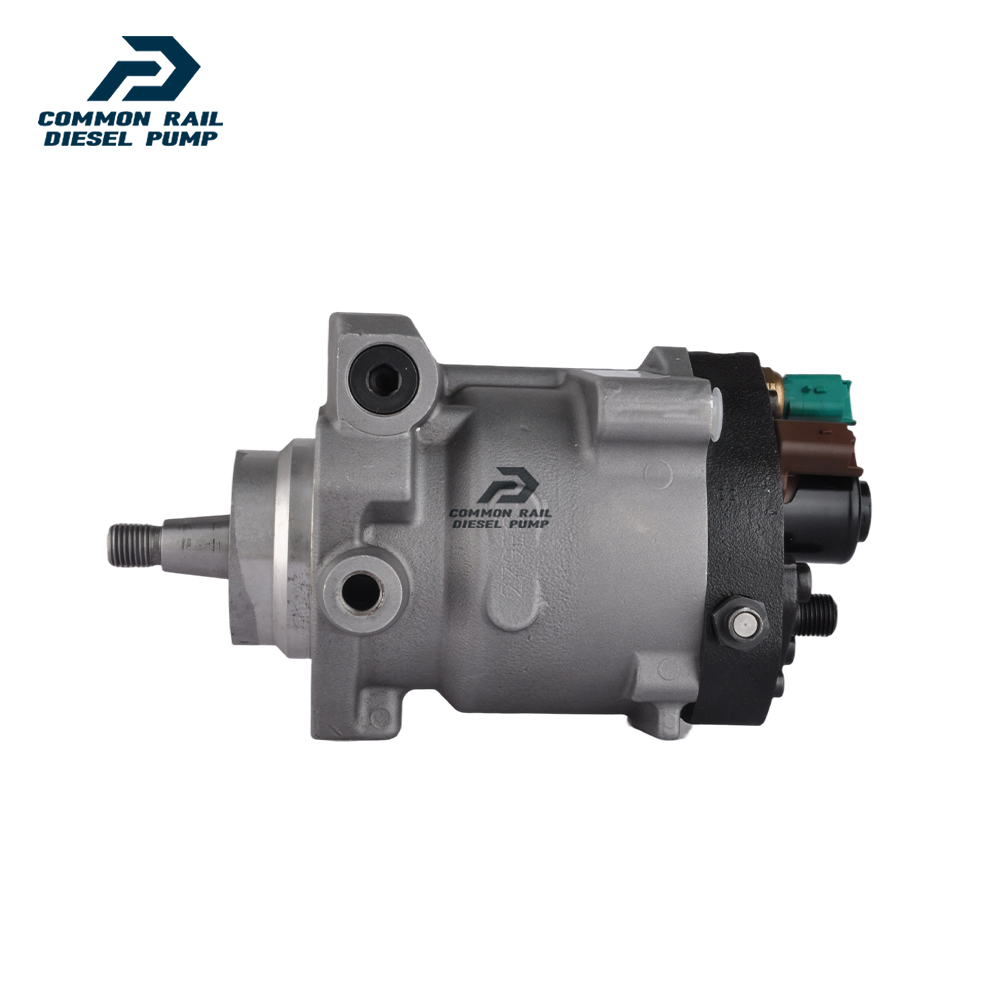

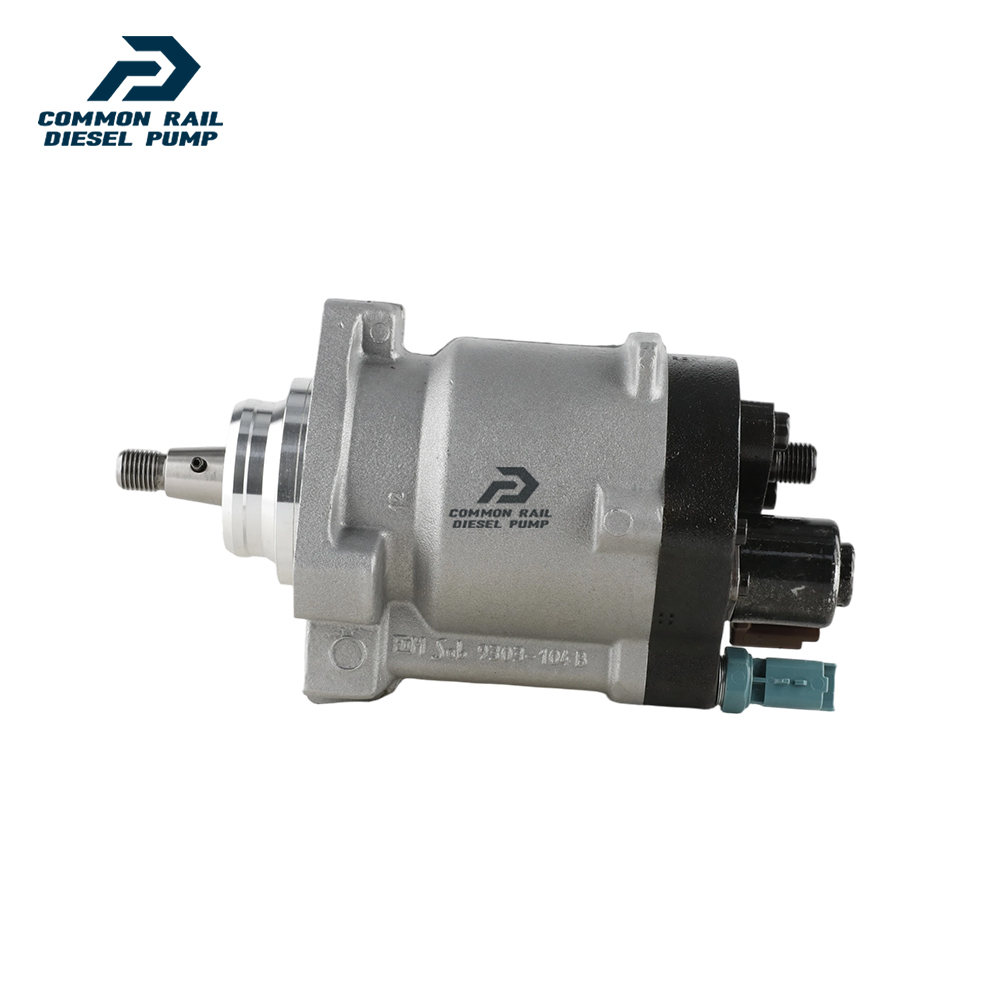

1. 10R-8900 Common Rail Diesel Pump Utilized Location

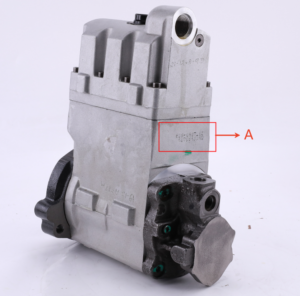

- Example: The code of the common rail diesel pumpis shown as follows

| NO. | Name |

| A | brand, logo, part number |

2. Reasons of 10R-8900 Common Rail Diesel Pump Not Working Normally

(1) There is air in the oil circuit of the engine fuel system.

(2) Vehicle common rail diesel pump oil supply system is not normal.

(3) Engine common rail system oil leakage or pressure limiting valve damage.

(4) There is a short circuit, cutting out and poor contact in the wiring harness connected to the common rail diesel pump of the vehicle.

(5) The long-term placement of the common rail diesel pump causes the anti-rust oil to solidify, and the internal components are stuck or the oil holes are blocked.

- Before installing, carefully check whether other components in the common rail system are damaged so as to prevent the common rail diesel pump from not working properly after being replaced.

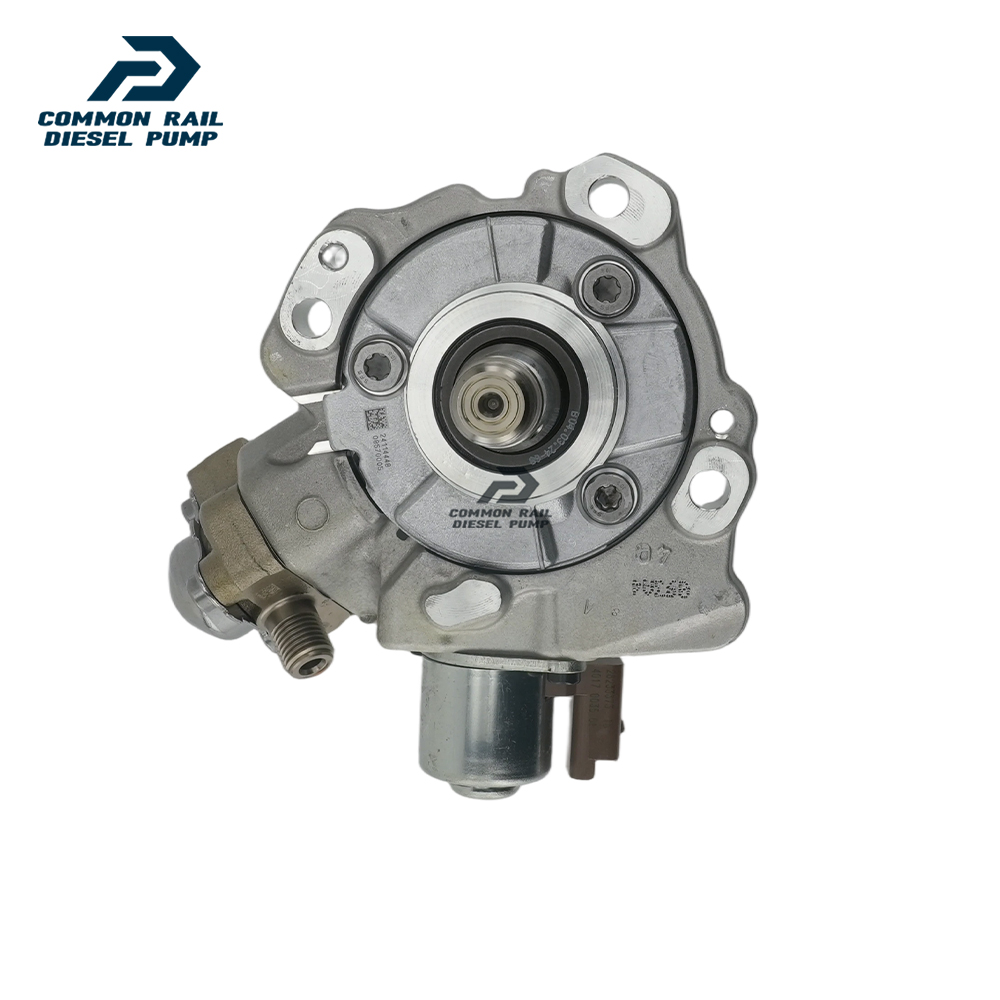

3. 10R-8900 Common Rail Diesel Pump Installation

- 10R-8900 Common Rail Diesel Pump Installation Precautions:

- The replacement of the common rail diesel pump must strictly follow the electrical system, the approved pressure of the low-pressure fuel intake system, the approved pressure of the high-pressure fuel circuit system, and fuel system replacement consumables requirements (including the low-pressure fuel circuit system filter and the high-pressure fuel circuit) specified in the vehicle engine maintenance manual.

- When install the common rail diesel pump, strictly follow the manual of replacement of wearing parts of the fuel system, cleaning requirements for the connection between the fuel system and the common rail diesel pump, the fitting clearance of the common rail diesel pump connection, the installation angle and tightening torque of the common rail diesel pump, the fitting clearance of the intake system, and the fitting clearance of the exhaust system, so that to ensure the service life of the engine and the normal operation of the common rail diesel pump.

- When installing the common rail diesel pump on the engine, it is necessary to clean the engine block, cylinder head and other parts connected to the common rail diesel pump, and ensure that there is no dust, carbon deposits, water, rust spots, etc.

- If don’t replace new washer shim, it can lead to: deformation of common rail diesel pump, oil leakage and air leakage, which will cause serious damage to the common rail diesel pump and common rail diesel pump to break and cause damage to the engine.

- When installing the common rail diesel pump on the engine, please carefully check the components related to the installation of the common rail diesel pump are not deformed, such as the common rail diesel pump pressure plate, screw, common rail diesel pump rod and other accessories, and install it in strict accordance with the operation steps of the engine maintenance manual.

- It is forbidden to operate the bare common rail diesel pump for a long time in an environment with serious dust pollution and corrosion to iron products.

- It is forbidden to operate the bare common rail diesel pump for a long time in a strong magnetic field environment.

4. Copyright Statement

This material is protected by copyright under www.commonraildieselpump.com and Shenzhen Shumatt Technology Co., Ltd. Unauthorized use, including reproducing, distributing, modifying, or creating derivative works, is strictly forbidden without prior written consent. For academic or non-commercial purposes, permission may be granted, provided proper credit is given, including the original name, title, and a direct link to the source.

If you wish to use the “10R-8900 Common Rail Diesel Pump Technical File” or have any questions, please contact hison@shumatt.com for further information.